The end of this month sees an important conference, to be held in Bremen, Germany from 27 to 29 October, 2014: It is the 5th International Conference on Wind Turbine Drivetrains. What do we mean by the drivetrain for wind turbines?

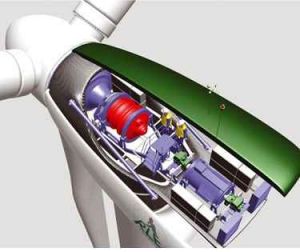

For modern horizontal turbines, the components are as follows:

- blade or rotor, which converts the energy in the wind to rotational shaft energy;

- a drive train, which usually including a gearbox and a generator;

- a nacelle – the housing that holds the drivetrain and other components

- a tower , usually monopole, that supports the rotor and drive train; with a ladder either inside the tower or externally to facilitate maintenance.

- other equipment, including controls, electrical cables, ground support equipment, and interconnection equipment.

In the wind power industry, the debate on which generator and converter option makes for the best modern wind turbine drive trains is still raging. Numerous technology experts and industry commentators promote the use of the double-fed induction generator technology, whilst expressing doubts about the advantages of the permanent magnet generator (PMG) approach. The Switch wants to set the record straight and explain why PMG with a full-power converter (FPC) is by far the best technology, regardless of which key decision-making criteria you use.

A big challenge for the conference is to get the industry to fully understand the advantages of advanced drive trains that lead to better performance. One aspect of the challenge is to show that a more expensive but sophisticated drivetrain arrangement can prove to be cost-effective in the long run through increased longevity and improved performance. It is sometimes claimed that permanent magnet generator (PMG) and full-power converter (FPC) drive trains are more expensive than double-fed induction generator (DFIG) drive trains. However, when every investment and operational factor is taken into account, PMG + FPC drive trains work out to be a cheaper, more cost-effective option over the total life cycle of the turbine, despite higher upfront costs. PMG designs have a comparatively low number of electrical faults and failures. The annual service costs of PMG technology can be up to 30 percent lower than the service costs for DFIGs.