Quindo FDMG1.5 – High Performance 1.5mW Wind Turbine System from MyWindPowerSystem

This amazing Wind Turbine manufactured for us by Foshan Quad is specially designed for low and medium wind speeds. The FDMG1.5 wind turbine – with a new rotor blade design and tower version of 65m hub height – guarantees excellent yields in the 1.5 mW category, even at inland sites. Its 70.5m rotor diameter and 65m hub heights enable the turbine to make efficient use of the prevailing wind conditions at the respective sites to produce sufficient electrical energy. This machine is most suitable to supply electricity for factories, feed the local grid, low cost up- scaling and addition to existing wind farms, on-shore and off-shore projects.

The turbine is output controlled by variable speed and allows the FDMG1.5 to attain maximum operation efficiency without increasing operating loads in the full and partial load ranges and at the same time prevents undesirable output peaks thus guaranteeing excellent yield and a high quality of power fed into the grid. This turbine is a flagship of precision and advanced Chinese engineering. 5 years Warranty on all parts!

Complete System includes:

- Generator

- Gearbox

- Hub

- Nacelle

- Tower

- Blades

- Pitch Controller

- Yawing System

- Hydraulics

- Break system

Price FOB: Foshan – China

Incl 5 years warranty on all parts

Delivery lead times is 4 month – See Terms & Conditions

OFF-Grid System

$1,698,500.00

Optional Grid-Tie Inverter:

To include Grid-tie Inverter System add

$300,100.00

Technical Specification Quindo FDMG1.5 Wind Turbine System:

- Rated power 1.5MW

- Power control Variable speed and Pitch adjusted

- Rated wind speed 12m/s

- Cut-in wind speed 3.5m/s

- Cut-out wind speed 25m/s

- security rank IEC II A

- Designed lifespan 20years

- Environment temperature -30℃ ~ +41℃

ROTOR

- Number of blades 3pcs

- Rotor diameter 70.5m

- Hub apex height 65.1m

- Rpm of rotor 12-20rpm

- Sweep area 3904

BLADES

- Blades length 34m

- Blade model DU-FFA-DU

- Material GFR-Glass-fiber Reinforced Resin

- Weight 4450KG

PITCH CONTROL

- Working way electromotor pitch adjust, independently blades adjust

- Pitch –controlled 4-points double row angular contact ball slewing ring with inner ring gear bearing

- Pitch adjusted rate 7.5 /s-12.5 /s

- Pitch adjusted angle range -94

- Battery lead acid, 250-300VDC

- Slip ring 29 rows

GEARBOX

- Type One stage planet gear/two stage parallel axis cylindrical inclined gear

- Inclined angle of main axis 5

- Ratio 0.104166667

- Oiling mixed lubrication

MECHANICAL BRAKE

- Position high speed axis

- Working way passive brake, spring locked, press and operate the brake

YAWNING SYSTEM

- Working way Drive motors active yawing

- No. of motors 4 units

- Yawing axis double row external gear 4 points contact ball bearing

- Yawing brake motor brake sticking, 6 hydraulic brake clips

GENERATOR

- Type Doubly-fed asynchronous wound generator

- Rotational speed 1000~1800rpm

- Rated voltage 690V

- Frequency 50Hz

- Seal rank IP54

- Cooling forced air cooling

- Converter rotor-side converter, PWM Modulation IGBT

COUPLING

- Model KTR RADEX-N

- Max. deviation of alignment 1.5

- Dynamic balance rank 6.3

TOWER

- Type 3 sections tapered tubular steel tower

- Height 63m

- Max. diameter 4260mm

CONTROL SYSTEM

- Core processor ARM embedded system WP4000

- Communication Industry bus line CAN Open

- Components cabinet in generator case, cabinet under tower, power switch cabinet

WEIGHT

- Turbine weight 30 Tons

- Generator case 50 Tons

- Tower weight 93.6 Tons

- Total weight 173.6 Tons

SECURITY SYSTEM

- Full wind span electromotor pitch adjust aerodynamic brake;

- Mechanical high speed axis associated brake;

- Equipotential lighting protection system;

- Manual yawing function

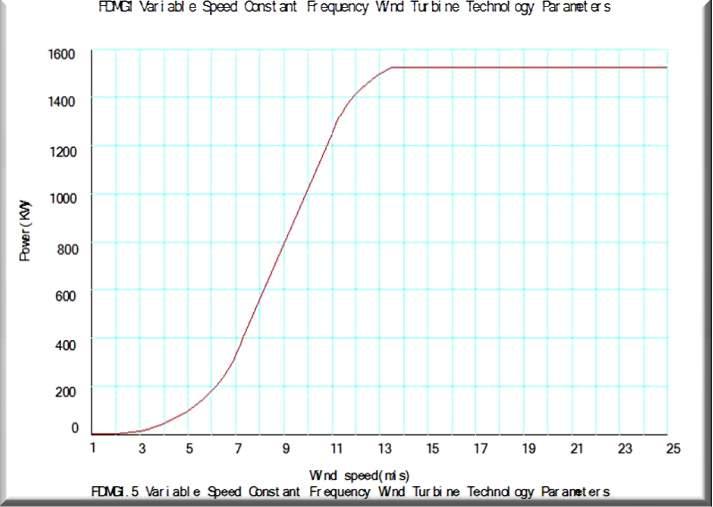

Power Curve

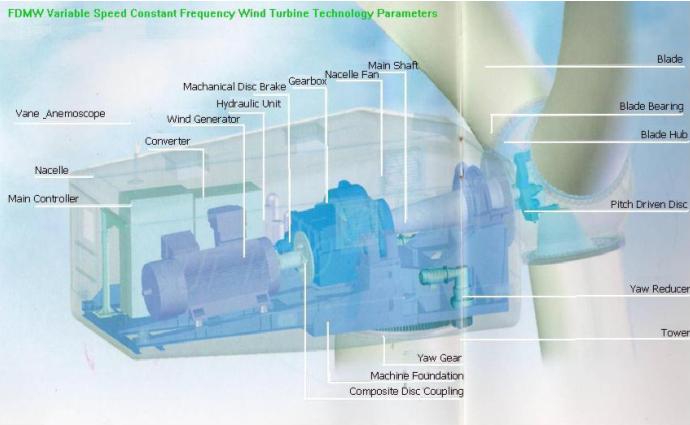

Internal Structure

Nacelle Series

Nacelle Body

Gear Box

Pitch Control – Yaw Control – Brake & Cooling System

Manufacturing & Test Assembly

Blades Finish

Example of a Wind Farm Field Construction Design for the FDMG1.5

- The required set floor space for one unit of the FDMG1.5 MW wind turbine with 70.5m rotor diameter is: 3904 m2

- A 50MW wind farm would require 33 sets of 1.5MW wind turbine with a total required floor space of 1,912,480 m2

- MyWindPowerSystem can assist in arranging installation of the turbine and adjustment set up

- Typical charge (subject to location)

MyWindPowerSystem.com and the MyWindPowerSystem logo are trademarks of MyWindPowersystem.com in the US and other countries

To purchase please contact us