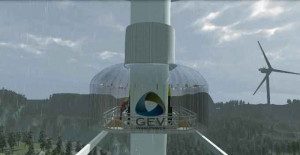

One of the most expensive, and sometimes dangerous aspects of the creation of wind farms, is not just the initial erection and commissioning, but the maintenance that is regularly required to make sure the turbines operate at optimum efficiency. A few companies have tried to perfect some kind of artificial environment to protect the personnel effecting repairs and to protect the cleaning equipment and the replacement parts. GEV has been working on this issue for some time.

GEV Wind Power’s prototype habitat structure is now ready for serious testing and is likely to revolutionize blade maintenance on wind turbines in farms in remote, high, or difficult locations. The prototype was unveiled at the RenewableUK show in November 2014 and created quite a stir. The GEV Habitat has been designed to create a weather-protected environment from which to undertake temperature and humidity-controlled maintenance. This should dramatically reduce time lost due to bad weather. This is a serious problem- inclement weather currently cancels 40 percent of planned maintenance days, and extends essential repair works beyond the favored May-October cycle. GEV Wind Power is developing its initial version with access platform provider, Belgium’s Power Climber Wind.

GEV Projects Director Alastair Gadney (pictured below) comments:

“We’ve made great progress with our prototype and are ready to start 2015 with ground-based trials at the National Renewable Energy Centre blade test facility, Blyth, Northumberland. Our view was to complete these before February in preparation for on-turbine testing. Ultimately, I foresee the GEV blade habitat making a hugely positive contribution to the life cycle costs of wind farms globally. From an operational perspective, early tests already show the ability to rapidly deploy the Habitat; we are looking at about five minutes for the habitat to be mounted to the platform and then less than 3 minutes to inflate the whole structure once in place.”

So what’s the bottom line in terms of money saving or production increase? The Habitat is expected to save the wind energy sector up to five lost days in each maintenance season, potentially returning a minimum of a 1-2% increase in annual energy production. Coupled with longer working days due to the ability to affix lighting gantries to the access platform and a longer maintenance season due to the weather protection, Gadney forecasts considerable benefit from the GEV blade habitat.

The basic idea is simple, Technicians will be able to travel to the top of the blade on the access platform, inflate the habitat and then travel down the blade to undertake maintenance. The company’s invention was given a boost last year when GEV Wind Power secured a grant from the Supply Chain Innovation for Offshore Renewable Energy (SCORE) funding program to bring forward the development of its habitat structure.

The platform is designed to be used on both onshore and offshore turbines, with an onshore field trial expected to begin soon this year. Habitat structures are not a totally new concept- they have worked well in the oil and gas sector for many years, but the migration of the concept across to wind farms was a new one.

“Wind speeds, rain, temperature, and humidity all significantly impact an engineer’s ability to complete scheduled

GEV will be at the EWEA Offshore 2015 conference in Copenhagen in March.